Microfluidics: Complex structures in hard-brittle materials

Microfluidics deals with the control of small fluid volumes and is classified as a key technology in analytics. Possible applications of microfluidic components can be found, for example, within biotechnology, drug discovery or (point-of-care) diagnostics.

Exemplary applications:

- Lab-on-a-chip

- Organ-on-a-chip

- Microanalysis systems

- Microreactors

In particularly demanding microfluidic applications, the advantages of hard-brittle materials such as glass outweigh their disadvantages:

Glass | Polymer | Ceramic | |

|---|---|---|---|

Optical properties | +++ | + | -- |

Chemical resistance | ++ | o | +++ |

Surface characteristics | ++ | o | -- |

Thermal stability | ++ | + | +++ |

Hydrophilicity | +++ | - | / |

Shelf life | + | - | +++ |

Reproducibility | ++ | o | / |

Coating capability | + | o | -- |

NRE costs | + | -- | -- |

Price per piece (series) | - | +++ | -- |

Source: MF Consortium of CfBI "Desing for Microfluidic Device Manufacture Guidelines", V5.

Exemplary Materials:

- Fused silica

- Borosilicate glass

- Calcium fluoride

- Zerodur

- Zirconia

- Silicon carbide

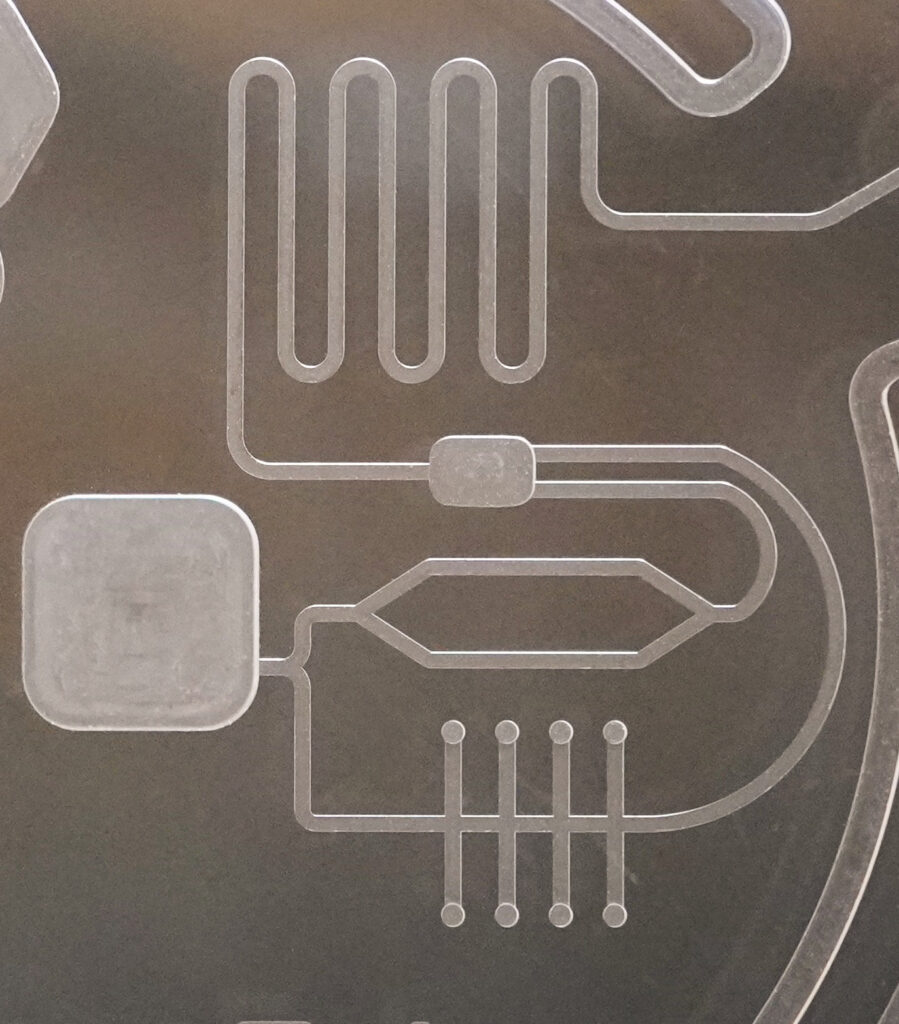

Manufacturable geometries:

- Micro holes

- Wells

- Reservoirs

- Complex 3D channels

- Branches

- Threads

- Inlet/outlet ports

- and others...

Due to our high-precision 5-axis CNC machining process, three-dimensional microfluidic structures made of glass can be produced economically even for small batch sizes and complex geometries. An application-specific selection of different hard-brittle materials (e.g. calcium fluoride for applications in Raman spectroscopy) can be made.

Our technology offers the following advantages in comparison to available manufacturing alternatives:

Etching processes | Laser processes | Selective laser etching (SLE) | ShapeFab (combined CNC machining) | |

|---|---|---|---|---|

| Fast prototyping / small and medium batch sizes | 𐄂 | ✔ | ✔ | ✔ |

| High volumes | ✔ | 𐄂 | 𐄂 | 𐄂 |

| No use of environmentally harmful chemicals | 𐄂 | ✔ | ✔ | ✔ |

| Low heat input into the component | ✔ | 𐄂 | 𐄂 | ✔ |

| High aspect ratio | 𐄂 | ✔ | ✔ | ✔ |

| Selective polishing | 𐄂 | 𐄂 | 𐄂 | ✔ |

| Vertical channel walls | 𐄂 | 𐄂 | ✔ | ✔ |

| Transition of different channel depths | 𐄂 | 𐄂 | ✔ | ✔ |